When I started using riflescopes as a shooter, I had no knowledge of what scope ring lapping was and its benefits or downsides. When I started hearing the term ”lapping,” I thought it was about adding some piece of paper or cloth to the rings to make the scope to be in perfect alignment. However, I was wrong, but that’s history now because I have carried out the lapping process several times.

Image Credit: Warnescopemounts

I have gotten so many questions on this topic from both newbies and professional shooters, and most of the questions usually relate to the time and need for lapping a scope ring set before installing it. Questions like, when should I lap my scope ring? Why may I need to lap my scope ring?

There are so many other questions about lapping but there is just one thing you need to know first before others, “The Purpose.” The purpose of the lapping process is to improve contact between the body of the scope and the inner surface area of the ring itself.

Why this? When rings are manufactured, they may not be perfect even in terms of their internal area, or the ring may contain defects that might harm the surface of your riflescope body and affect your scope accuracy.

Can You Avoid Lapping

Over the years, I have used various types of scope rings; I’ve discovered that the more I’m willing to pay for a set of scope rings, the less likely I am going to worry about lapping them before mounting them on a gun receiver. This means I can actually avoid the whole stress of lapping a scope by getting a high-quality scope.

Let us say I got two scope rings; one that costs less than $100 and one that is worth over $500. The difference in price should reflect in the quality of the scope ring. Meaning the manufacturer must take extra time in the production of the high-end scope ring to ensure that it would not need lapping after production. High-quality scope rings are less prone or less likely to require lapping.

When it comes to Chinese scope rings, you should just get a lapping kit that has every single lapping tool you will need. Again, the distinction lies in the product manufacturer and the quality from the start.

What Is The Importance Of Lapping A Rifle Scope Ring?

This process is done when it becomes necessary. Assume you purchase a nice-looking pair of scope rings but observe a series of lines on the ring’s inner surface material.

These finely cut bands might be uneven, putting a strain on some parts of your scope tube. Even the smallest metal shavings or uneven metal lines can cause harm to the body of your scope.

When you place the scope on the rings and tighten the mounting ring screw that joins the top half of each ring to the bottom half, some pressure is formed on the tube. If the scope rings are not constructed equally with a very smooth surface, more pressure would be induced in one area than others.

The pressure created when screwing the scope rings can occasionally cause damage to the scope’s internal workings or the housing of the scope (tube). It may also result in scope alignment concerns.

What You’ll Require For Lapping A Scope Ring

What equipment is needed for lapping a scope ring? If you’re not a gunsmith, then you are generally unequipped to handle lapping using common household equipment; therefore, you will need to purchase at least a basic lapping kit that has the needed lapping tool.

Would getting a lapping toolkit be a good idea for you? Maybe, let’s find out. Depending on your budget or possibilities of repeated use. If I were you, I would think carefully before proceeding to purchase a toolkit that contains a lapping compound, lapping bar, lapping bar handle, alignment bar and others. You should only consider this purchase if you plan on doing a lot of general mounting or scope transfer work.

Assume you’re mounting a deer riflescope and don’t plan on doing it again anytime soon. Purchasing the needed tools at that point becomes unnecessary. If you insist on learning how to lap scope rings yourself, this is the typical strategy adopted by a do-it-yourself home gunsmith.

How To Lap Scope Rings

Before you start working with your gun, always ensure that it is unloaded to avoid an accidental discharge.

Alignment

If you plan on mounting scope rings regularly, whether for a small local gun shop or for your friends, the instruments used for this trade are simple to obtain from a gunsmith product supplier.

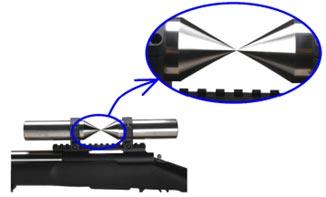

A scope base and scope ring centring mechanism are recommended first. This unit consists of a pair of machined tools for alignment (Alignment rod) that face each other at a point when they are positioned in front of each other on the scope mount ring. The cylinders, also known as an alignment rod or a lapping rod, are placed on the rings and slightly pushed forward towards each other. The tip of each lapping rod must perfectly line with the other.

Any deviation from this alignment means the scope base has been installed off-center. Most times, this is due to incorrectly aligned base drill holes. The drill holes on the front receiver ring and rear receiver ring are supposed to be straight so that the lapping rod pointed edges can touch each other. While I’ve not seen this misalignment problem in a custom-built receiver hole, I have seen it in a few factory installations.

Alignment is usually checked before you lap and after you lap to measure the extent of deviation before lapping and the correctness after lapping the rings.

Polishing

Assuming you’ve completed the ring alignment checks and it is in place, you’re good to go. The bottom and top rings are then polished with a special lapping compound that wears off from the surface it was applied on, leaving you with a flawlessly smooth pair of rings.

You’ll need a lapping tool, which resembles a bolt action but is one inch or 30mm in size or depending on your scope tube size.

To begin the polishing process, the bottom scope rings must be securely fastened to the scope base, which is already attached to the receiver of the rifle. Do the following next:

Position the lapping tool on top of both bottom ring assemblies, just like you would put your scope on the rings when you want to mount the scope. With the lapping bar in position on the ring top, screw the top half to cover the rings on both sides. Do not tighten the rings yet; allow the lapping bar to travel forth and back over both the front and rear scope ring.

Use the handle of the lapping bar and a coating of lapping compound (silicon carbide abrasive) which you can get from gunsmith supply houses. Apply the lapping compound directly on the scope rings and gently stroke the lapping bar handle forth and back across the two rings.

This movement makes the lapping compound to remove the high points on the ring and remove all the small metal amours in the internal part of the ring. This will make you have a consistently smooth internal ring surface area.

Apply more lapping compound as you tighten the setup a little after the first round of forth and back movement. While tightening, leave enough room for the lapping bar to continue moving over the scope rings since the goal is to remove another layer of metal amours on the ring surface with moderate friction.

Avoid applying too much lapping compound since it might get messy; it’s best to conduct a few touch-ups at intervals instead. When lapping a scope ring, take your time during the process, don’t be in a hurry so you won’t mess everything up.

Final Checking

After numerous repetitions, the internal layer of the rings ought to be smoother than it was and devoid of any anomalous dents or elevated spots. After cleaning your scope ring with this lapping process, a visual inspection will reveal areas where the bluing has been rubbed away – this is normal in this circumstance.

In most cases, the lapping method will restore between 80% – 90% of the ring’s surface to 100% smoothness to the scope body wall.

If you’re unsure or if you discover a spot that requires attention or provides some little resistance when mounting your scope, repeat the process until you’re satisfied with the results. You may now mount your scope and tighten the screws.

What Difference Would It Make?

Now I’ll be sincere with my readers once again. I won’t make up some stories about the benefits of this process. I hardly lap a scope ring because I use good quality scope rings to shoot anything from 50 yards to hundreds of yards.

In some cases, some scope users wrap a piece of Scotch tape over the body of the scope where the rings make contact. These tapes will fill up any tiny dents or scratches in the ring. This method has been used by hundreds of rifle owners, and there is hardly a case of damaged scope or other issues.

I understand that most bench-rest shooters strive for perfection. The type of precision required for hitting a single hole in a paper with five bullets. I am aware that these shooters would benefit greatly from knowing how they can lap a scope ring correctly.

Also, Long range shooters who are aiming for more than 1000 yards are looking for something that can shave off those tiny metal amours on their scope rings to make them hit the steel target miles away. A correctly aligned and lapped scope mount will surely assist in accuracy.

Lapping can surely help you achieve maximum mechanical precision.

There is nothing wrong in lapping a scope ring, but ensure you understand what and why you are getting into it before you begin.

Mike Hardesty is a published freelance gun writer. He also possesses specialized expertise in rifle scopes With dozens of articles and reviews published in Pew Pew Tactical, Snipercountry.com, and TTAG (The Truth About Guns), Mike is considered a firearms expert. His special area of expertise is handguns.

Mike is a long-time shooter. He has been punching paper targets, taking deer and other game and shooting at competitions since about 1975. Other related pursuits include reloading and bullet casting. He currently reloads for over 10 calibers, both handgun and rifle. His reloads, particularly for 9mm, were in great demand during the height of the ammo shortage among family and friends. He donated hundreds of rounds to informal shooting sessions. He was quoted as saying “I do not sell my reloads but I sure will help my guys shoot ’em for free!”. He has a few cherished firearms that he has inherited or otherwise procured — those are his favorites.

He earned B.S. and M.S. degrees from Indiana State University in 1974-1975.

He’s a firearm experts and is the founder of mhardesty.com.